Time:2015-03-09 by www.SignChinaSign.com

In the printing business industry we can normally hear those words: “my print head is clogged” ,the print head is really clogged? If you need to make sure the print heads is really clogged, you first need to make clear about the definition of CLOG. If we put it in a very straight definition, the clog of print heads means the nozzle of the print heads is blocked. And actually this really happens that the nozzle blocked. This phenomenon has something to do with the Ink, the environment and the static. Why? We need to look for the answer from the reason of the clog. Actually the reason of clog is usually not what we usually think as big ink microdot. Let alone the size of ink microdot ,let’s first understand the structure of the print head and the ink supplying system, and see if we put the reason as big ink microdot is correct or no.

In the printing business industry we can normally hear those words: “my print head is clogged” ,the print head is really clogged? If you need to make sure the print heads is really clogged, you first need to make clear about the definition of CLOG. If we put it in a very straight definition, the clog of print heads means the nozzle of the print heads is blocked. And actually this really happens that the nozzle blocked. This phenomenon has something to do with the Ink, the environment and the static. Why? We need to look for the answer from the reason of the clog. Actually the reason of clog is usually not what we usually think as big ink microdot. Let alone the size of ink microdot ,let’s first understand the structure of the print head and the ink supplying system, and see if we put the reason as big ink microdot is correct or no.

The current printer with xaar128 normally have filter which have filtration size below 10μ m, but in the print head there is a filter layer which have filtration size below 8μ m. Obviously if there have bigger ink microdots ,it would be filtrated away by this second filter layer in the print head, and won’t block the print head, besides as personally I know ,the ink manufacturer normally use 1μ m filter to filtrate their ink. And why the clog problem also happens now? Well, it is because there always have the sediment of ink which you used before. Although the ink is filtrated , but in the print heads nozzle there are sediments which can block the nozzles. but the ink in the market you can find already have big improvement in this point, so now the heavy clog problem is very few now. And below we make a analysis about many influence factors about the clog problem from the temperature ,the humidity, the controlling system of the printer, the static, and the cleaning ways which have something to do with the print heads and ink.

The changing of temperature and humidity has it influence to the print head and ink.

Before the printer left it’s production line , the factory would set a standard environment requirement of working temperature and humidity for it’s equipment, and why there is a such requirement? Because the stability of the ink can influence the print head, and the stability of the ink is influenced by many factors such as the glutinosity, strain in the surface, volatility ,fluidity etc, and the direct requirement which influence those factors is not decided totally by the production procedure, but the printer’s storage condition after working and the temperature and humidity in it’s working condition would also influence the ink. If the temperature is too high, the glutinosity of ink would go up, if too low, the glutinosity of ink would go down, thus this would break the standard environment condition of the ink , and you can see many break lines in the image, or even the declining spray lines of the printing. In another hand ,if the humidity is too low and temperature too high, this would cause the very high volatility of the ink , after the ink is dry in volatilization ,there would be condensate in the nozzles, thus influence your printing job. If the humidity is too high, the ink might also stick into the button of the print heads around those nozzles, and the printing image is not easy to dry, this would also influence your job. So you need to take care of the changing of temperature and humidity.

The print head is sensitive to the changing of temperature and humidity, as there is only very little ink storage in the print head ,and the ink supplying to the nozzle inside the print head is realized by the SIPHON phenomenon. Thus the changing of temperature and humidity would break the balance in the process of siphon ink supply, and then would make extra heating in the print head when it is printing, the ink is keeping the balance in the siphon process, and the print head would generate heating when it is working, and then if there is no air conditioning in the printing room (this normally happen in The Autumn and the Spring),then big influence to the printing quality would appear, the same ink which worked before now can not work normally, your print head can not work normally. So after this happen, the only way to solve this problem is to control the temperature, make sure the changing of temperature in your printing room no more than 3℃-5℃。

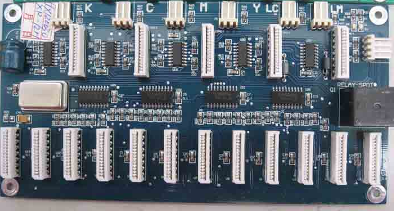

The influence of print head controlling system to the print head

The print head is working under the standard voltage and the firing pulse frequency, everybody knows about this point. But only very few know the standard frequency for this , Xaar 128 working at the standard pulse frequency at 4k/second and 8/second,have 2 different mode, And the current printers all use the 4k/second 200dpi or 370dpi print head, except the Nur printer. This standard frequency can not be overrun. It’s just like a lamp under 220v standard voltage, if working in 250v,the lifetime of the lamp would be reduced, and if in 380v,the lamp would be burned, thus the bad aftereffect of the overrun in frequency in print head is obviously.

Because the ink flux printing speed under the standard pulse frequency of xaar128 can not meet the requirement of color saturation in high speed and heavy duty job ,many printer manufacturer bring up the voltage and the pulse frequency of the print head according to it’s some client’s needs, this would bring high printing speed and good quality image, but it’s under the cost of the short lifetime of the print head with a big print head depreciation. And now someone even says the rate of the print head depreciation is 0.5-1 RMB per square meter. This means if one printer which print out 10000 square meter ,it would have to change 2 -4 print head per month, this depreciation cost of print head is equal to the cost of the ink it self .And because of the bring up of the speed of ink flux, there would be a shortage of inside ink supply in print head, then you need a more smoothly ink supply system, but obviously today the ink you find in the market can not meet this requirement. And because the ink supply inside of the print head is realized by SIPHON phenomenon (except the Nur printers), the usage of siphon in ink supply itself have the problem in negative pressure, and then how can you make a smooth ink supply under this problem? And so during the printing there are many break-off lines due to break off of ink supply, and if this happen very often and long time,there would be some declining printing lines and dots during printing.

Lets talk about the voltage of print head, because the voltage of the print head would decide the extent of the bending of the piezoelectric ceramic that work inside of the print head ,so the high voltage would result to a high flux of ink printing. The recommended rating voltage of xaar128 is no more than 35V, and it’s lower the better as long as it not influence the image quality. According to our experience ,if the voltage is more than 34v then it would very possibly cause the ink break during printing frequently, and also cause the short lifetime of the print head. We have talked about the higher voltage of the print head would result in higher extent of the bending of the piezoelectric ceramic ,and if in the same time the frequency is also overloaded, the piezoelectric ceramic is very easy to fatigue and break down, while the too much lower voltage would influence the color saturation, So the 28v -34v is the more proper voltage for print heads.

Static influence to Printer and ink.Normally nobody notice this problem. The xaar128 belong to soft piezoelectric print head, during the printing there would be many static caused by the friction between the material to the roller, if it can not be removed away, it would really influence the regular working of the print heads. And flying track of the small ink drop would be easily influenced by the static, which could result in disordered printing , this make the ink drop land to the wrong place on to the material, And if the static is too strong, this might just damage the print heads, and besides, the computer and printing system is easy to crash down or have disordered code under strong static, so we need to use the right way to remove the static during our printing , to have a well grounded line is the good way to solve this problem.

Strictly speaking, the Ground line should not connect to the Public ground line, because actually you don’t know during the other electric lines if there are other machines which would make static or not. So in our experience, there should be a independent Ground line for each machines.

The right way to lay the Ground line is to connect the ground lines into one copper board with no less than 0.5 square meter in size and imbed this copper board 1.8meters deep into the earth, make sure the earth is wet and then pour some Salt water into it.(Here the connect together means Weld them together by welder, so you need to weld the ground wire into the copper board, otherwise the connection would break after rust).After the ground line is well laid, you need to check the Static after the machine working one hours latter, The right way to measure this static then is to use a multi-meter ,use it’s AC 200 mode,and one detect leg connect to the 220V DC power supply input neutral wire, and another leg connect to the ground wire, then the absolute value is the remaining static value. This value should be below 1 Ohm. You need to test this number frequently, if the value is over 1 Ohm or fluctuate very big, then you need to check the ground connection. Many printer owners think the Ground setting is a once done and for ever things, and ignore to checking the Ground connection, and in all over China this is a normal mistake, only when the print head or electric board is burned then they get this lesson.

The influence of static to the ink drop which results in the clog of print heads, this is easily misunderstood as the influence of ink drop itself, so when print heads are clogged you still don’t know the real reason. Thus when you find anything unusual during the print job, you need to check if the static is eliminated away.

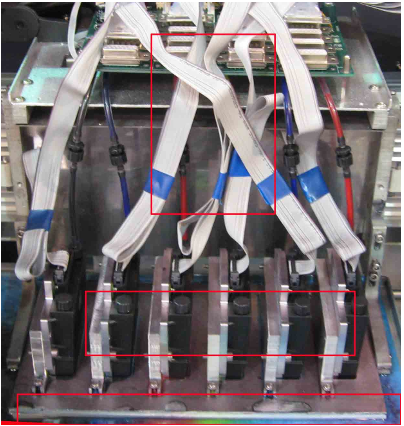

The influence of the cleaning method to print heads.

The Xaar-128 print heads have a film layer on it’s surface, and the nozzle holes on this film which is made by laser cutter would decide the resolution of the print heads. Strictly speaking it is not proper to scratch this film by any paper of any materials. But now many printing company are using the sponge or tissue paper to clean the print heads.

The sponge is very soft material relatively, but it would harm the print heads if be used not properly. To much pressure in cleaning with sponge would make the hard stick inside of the sponge touch the film surface which would result in the damage to the nozzles, and this would also result in the disordered ink dropping directions, or result in the conglomeration of ink in the surface of the film surface, in all this would damage the print heads.

The print heads cleaning cloth is originally used by the Vutek machines, which is a cloth without dust, because the print heads of vutek machine is made out of steel, so it is not easily got damaged. And the cleaning cloth which from Vutek is very soft, and usually the cleaning cloth in the market are normally the non-woven fabric, the material is coarse relatively ,to clean the XAAR-128 print heads with this fabric is very dangerous relatively as the xaar-128 print heads is easily got damaged .

So what way is the proper way to clean the print heads? The automatic cleaning way of Nur printer is a good example. What we need to do is just buy a sprayer, and spray the cleaning solution onto the print heads, and then use the vacuum cleaner to suck it, in this way there is nothing touch the film surface of print heads thus do no harm to those nozzles. But also need to take care if there are any burrs in the tube of the vacuum cleaner, in case those burrs scratch the nozzles.